WHAT IS MULTIBEAM ECHO SOUNDING (MBES)?

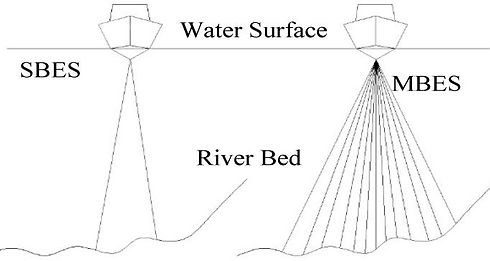

SINGLE VS MULTI BEAM COMPARISON

Single Beam Echo Sounder (SBES) measures depth at a single spot directly below the sensor, requiring multiple survey lines to cover an area.

Multibeam Echo Sounder (MBES) returns multiple depth points across a wide swath with each ping, dramatically reducing survey time.

MBES VS SBES ADVANTAGES

MBES Benefits | SBES Benefits |

|---|---|

Higher resolution bathymetric models | Longer depth range capability |

Complete seafloor mapping with swath coverage | Dual-frequency options available |

Better productivity - requires fewer survey lines | Less dependent on sound velocity profiles |

Significantly better data density/resolution/bathymetric coverage | Simpler operation, more accurate for single points |

%20-%20New%20drone%20multi%20beam%20system%20-%20Copyjpg_Page9_Imag.jpg)

WHY CERULEAN SURVEYOR 240-16 MBES?

TECHNICAL SPECIFICATIONS

-

Ultra-lightweight: 790g in air, 145g in water

-

Integrated IMU for pitch and roll compensation

-

16-beam configuration optimal swath coverage

-

240kHz frequency for shallow-medium depth

COMPLETE SYSTEM COMPONENTS

HARDWARE PLATFORM

-

M350/M400/compatible drones

-

SkyHub + True Terrain Following

-

MBES on foldable arm

-

Integrated GPS/GNS

SOFTWARE SUITE

-

UgCS Desktop + Companion

-

SkyHub MBES package

-

BeamworX processing

-

Hydromagic support (coming)

DATA PRODUCTS

-

Cerulean SVLOG format

-

LAZ point cloud export

-

Industry-standard formats

-

Professional deliverables

DATA PROCESSING WORKFLOW

Professional MBES data processing workflow similar to LiDAR processing - delivering industry-standard point cloud products

Raw Data Collection

Cerulean SVLOG Format

Raw multibeam data automatically logged onboard SkyHub during flight operations

-

16-beam multibeam data

-

Integrated IMU for pitch/roll

-

GPS positioning data

-

Real-time data validation

Patch Test & Calibration

BeamworX AutoPatch

Automated calculation of pitch/roll/heading corrections for proper swath alignment

-

Specific data collection patterns

-

Automatic stripe alignment

-

Sensor mounting corrections

-

Quality control analysis

Final Processing & Export

BeamworX AutoClean

Professional data cleaning and point cloud generation

-

LAZ export as main product

-

Industry-standard formats

-

Automated outlier removal

-

Professional deliverables

SOUND VELOCITY CONSIDERATIONS

CRITICAL FOR ACCURACY

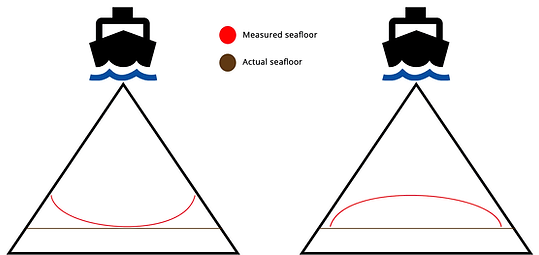

Sound speed variations affect beam geometry and depth accuracy:

-

High velocity estimates: "smile" effect (upward curve)

-

Low velocity estimates: "frown" effect (downward curve)

Recommended Profilers:

Teledyne Valeport SWiFT SVP

(FOB UK)

Hydro-Tech SVP1500

(FOB China)

When the measured (estimated) sound velocity is higher than it should be, a flat surface will bow upwards (eg. ‘smile’) and when it’s too low, a flat surface will bow downwards (eg. ‘frown’).